These days, packaging does more than keep a product safe; it tells a brand story, shares key info, and sets the tone the moment a shopper glances at a shelf. That is why food, beverage, chemical, and personal-care makers turn to precise labeling as a core part of their workflow. Working alongside larger automatic packaging machinery lines, modern labels go beyond slapping on stickers-they boost speed, meet rules, and strengthen brand visibility at every step of the supply chain.

In the sections that follow, we look at the added benefits a high-quality labeling system can deliver to manufacturers who plan to scale steadily, keep quality steady, and earn shoppers long-term trust.

Why Labeling Accuracy Matters in B2B Production

In large-scale manufacturing, there really is no wiggle room for labeling mistakes. Every sticker or print needs to go on straight, read clearly, and match the rhythm of the line. If it doesn’t, the plant can face:

- Regulatory fines

- Retail returns

- Confused shoppers

- Damaged reputation

- Extra waste and costly re-work

A dependable can labeling machine working alongside automatic packaging gear places labels perfectly, no matter the container’s shape, size, or line speed. This setup acts like a quality gate, giving each package the same crisp look that boosts brand visibility.

In B2B channels that feed retail or export shelves, solid labeling also feeds serialization, tracking, and the data rules set by regulators around the globe.

How Can Labeling Machines Boost Line Efficiency

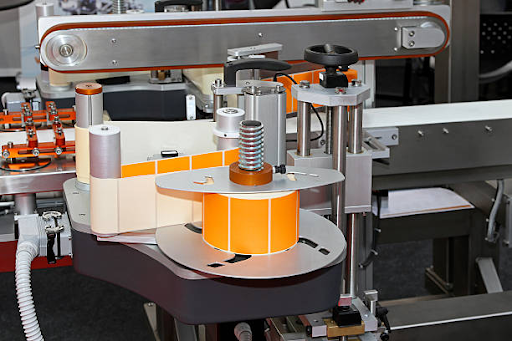

Labeling systems do more than make products pretty; they keep the line moving and shrink downtime when automation is done right. Modern machines grab and apply wraparound, front-and-back, top, or tamper-evident labels at a blistering pace without sacrificing accuracy.

Seamless Integration with Packaging Lines

Today’s laborers sit right between filling and sealing machines on the production floor, working in an almost concert-like manner. Because of smart drives and controls, they read product shape, space out each label, and shift speed whenever upstream or downstream units speed up or slow down.

Smart Sensing and Adjustment

Built-in cameras, optical sensors, and PLCs (programmable logic controllers) watch for four key things:

- Are the labels straight?

- Are the containers lined up?

- Is the label roll feeding at the right pace?

- Can the print—even a tiny expiry date—be read clearly?

If something looks off, an alarm sounds or the machine makes a quick fix by itself, cutting down the amount of hands-on attention needed.

High-Speed Labeling Without Compromise

Modern machines can burn through hundreds of labels each minute yet keep the edges sharp, never blurry and never peeling up. Thanks to fine-tuned servo motors and rollers that lightly press instead of squash, even cans with a small curve leave the line perfectly dressed.

When a can labeling machine and automatic packaging machinery share data in one system, they create a single, fluid workflow—fast throughput paired with rock-solid quality control.

Enhancing Brand Identity Through Advanced Labeling Capabilities

In crowded stores the label usually gets a split second to impress, and that tiny slice of time can decide a sale. A clean, bold label instantly suggests trust and quality, helping a product stand out in a global sea of choices while also reminding shoppers whose brand they picked.

Customization and Product Differentiation

Automated labeling machines now handle limited editions, regional SKUs, or multi-language labels without pausing the production line. Thanks to:

- quick-change label rolls

- modular set-ups for varied formats

- digital hooks for on-the-fly updates

- inkjet or thermal coding for live data

manufacturers can spin up fresh pack designs in minutes.

Premium Finishing Options

Many modern labelers also work with specialty stocks like metallic foil, embossed paper, or compostable film. These premium touches give products an upscale look, build shopper trust, and strengthen brand image on crowded shelves.

Traceability and Transparency

Today’s labels carry more than logos; they hold barcodes, QR codes, ingredient lists, safety seals, and dozens of other markers. That data gives firms complete traceability, meets global rules, and opens direct digital links for consumers.

For wholesalers, retailers, or large institutional clients, those details are often mandatory-and they must print and apply correctly every time.

Reducing Operational Costs and Waste Through Automation

Tape guns and hand labelers slow lines, boost errors, and waste precious stock. By linking a smart labeling unit to automatic packaging machinery, companies cut labor, shrink spoilage, and push overall line efficiency skyward.

Labor Savings

Automating the labeling process trims the number of people needed to put on and check each label by hand. That frees up skilled workers for smarter tasks, like keeping quality high or managing the line.

Label Waste Reduction

Modern labeling machines use tighter tension controls and precise feeds, so labels rarely snag or sit askew. Less waste of label stock helps factories reach their lean-production targets.

Predictive Maintenance

Sensors built into new machines watch for wear and give a heads-up before minor issues grow costly. Catching problems early cuts downtime and can even stretch the life of the equipment.

Consistency Across Product Lines

From soup cans to sports drinks to chemical drums, an automatic line applies every label the same way. That steady look helps keep a brand’s image strong no matter where the product lands.

What to Consider When Choosing a Labeling Machine for Your Operation

Picking the best system starts with knowing your package style, how fast you fill bottles or boxes, and any special label tricks. Here are four questions to guide your choice:

- Label Type: Pressure-sensitive, shrink sleeve, wraparound, top-and-bottom, etc.

- Container Format: Works with round, tapered, flat, or oddly shaped packages.

- Production Speed: Measures in units per minute, plus time for adding each label.

- Integration Needs: Should plug right into the existing packing line without major tweaks.

- Changeover Frequency: Features that let operators swap jobs quickly when runs are short or SKUs vary.

- Print-on-Demand Capabilities: Prints fresh dates, barcodes, or serial numbers in real time.

Custom-built systems usually deliver the best long-term return, merging tight accuracy with tough materials and the flexibility to grow with the business.

Conclusion

A can labeling machine does far more than stick on a label—it speeds the line, meets rules, cuts waste, and talks to shoppers. Pair it with automatic packaging machinery and you have a must-have setup for any maker wanting to scale while keeping product look and feel steady.

For B2B brands, putting money into these machines means every item leaves the plant with a tag that shouts quality and trust. As supply chains grow louder and shoppers demand more, labeling done right moves from nice-to-have to absolutely essential.