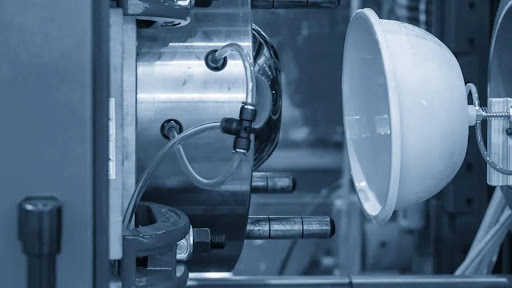

Today the manufacturing processes are of great importance in the success of any country. Today, injection molding is one of the most significant positions in modern manufacturing. As it enables the production of high-quality, reliable, and accurately shaped plastic parts for different industries. From the automotive industries to home appliances, and medical equipment to packaging industries, there is a growing need for new injection molding technologies. In this field, China is among many countries that actively develop injection molding and ranks among the leaders. The injection mold company china has paid much attention to technology development and applications. This enhances the efficiency of production and also enables the production of complex and customized products. This article has chosen to highlight the main developments in injection molding that are being driven by China’s key market players.

-

Customization and Rapid Prototyping Capabilities

The opportunity to develop individual approaches and quickly create prototypes has become one of the significant competitive advantages of the injection molding industry in China. Current manufacturers have also built capacities that enable them to address the customer needs for unique and customized products.

-

Specialization for Different Sectors

The Chinese injection molding manufacturers are well equipped to offer specific services and products for different sectors including automotive, electronics, packaging, and healthcare. This has positioned them well, especially in their ability to create molds that suit the needs of each industry. From vehicle components with specific functions to medical equipment with compliance issues, Chinese manufacturers are ready to respond to various customers’ demands.

-

Fast Prototyping by 3D Printing

Chinese manufacturers are increasingly accepting 3D printing technology to improve their rapid prototyping. 3D printing helps them to develop prototypes and new designs much faster than traditional processes. Using 3D printing technology, manufacturers can easily make adjustments, create new designs, and develop prototypes for customers before going ahead and ordering mass production. This innovation is widely beneficial for industries such as automotive and medical devices where speed of product development and accuracy are paramount. Integration of rapid prototyping reduces time to market and helps the manufacturers to operate competitively in the world market.

-

Multi-Component and Micro Injection Molding Innovation

Another growth area that has been observed in China’s injection molding industry is in the multi-component and micro injection molding technologies. These innovations allow manufacturers to produce more unique and complex products needed in today’s markets.

-

Complex Products Made by Multi-Component Injection Molding

Multi-component injection molding, 2K or 3K molding is a process in which different materials or colors are used in molding at the same time. This technique enables the fabrication of intricate parts made of dissimilar materials and with dissimilar characteristics in one step, e.g., hard and soft polymers or polymers of different colors. This technique has been used by Chinese manufacturers to create high-quality and multi-material products that are in industries such as consumer electronics, automotive interiors, and medical equipment. Multi-component molding has its benefits such as; Complex parts have better functionality, better looks, and need less assembling time. Chinese manufacturers have improved this process to achieve high accuracy, low scrap rate, and high repeatability, and therefore many companies often turn to Chinese manufacturers to supply them with complex and complex parts.

-

Micro Injection Molding for Precision Components

Micro injection molding is another technology that is gradually being adopted by Chinese key players. This process entails the creation of small and accurate components in terms of geometry and size which are applicable in medicine, electronics, and telecommunication. Micro-molded parts can be as small as a few millimeters, and the shape may be intricate and demanding of high levels of accuracy. Currently, Chinese manufacturers have created micro injection molding machines and tools that are designed to produce parts with a tolerance of microns. Such innovations enable them to fulfill the increasing customer demand for miniature parts in new-age technologies. The fact that China was able to manufacture such small and complex parts with high precision adds more to the credit of China in the field of injection molding.

-

High-Performance Materials and Green Technologies

Chinese plastic mold factory is adapting to the change by seeking ways how to use more environmentally friendly materials and sustainable solutions. Sustainability is a significant trend that represents the interests of consumers as well as the requirements for rational production.

-

Bio-Based and Recycled Materials

Another of the major developments in Chinese injection molding is the adoption of bio and recycled materials. Currently, many manufacturing industries are seeking other forms of plastics other than those derived from petroleum such as biodegradable polymers, bio-resins, and others. Biodegradable materials are produced from renewable resources like corn starch or sugarcane and have less impact on the environment than normal plastics. Environmental considerations have also gained importance in China where recycling has also emerged as a focus for many injection molding companies. When recycled plastic materials are used in the manufacturing process, there is little waste, and energy is conserved. Such a transition enables manufacturers to produce products that will conform to the sustainable development goals while delivering the best quality needed in different sectors.

-

Reinforced Thermosetting Plastics

Besides sustainability, Chinese manufacturers are also experimenting with new polymers for their lightweight and high performance. These advanced materials are necessary for industries where it is vital to decrease the mass of structures while maintaining their strength. With the help of new polymer composites, it becomes possible to create new parts that are lighter and stronger at the same time, which in turn will enhance the fuel efficiency and performance of vehicles and airplanes.

Conclusion

In conclusion, the injection molding industry in China has grown to become one of the most competitive in the world. This is done by constantly developing new automation technology, new materials, and new specialized molding methods. From intelligent manufacturing to green materials, and multi-component co-injection to micro-injection technologies, Chinese manufacturers are exploring the frontier of injection molding. This guarantees that China will continue to lead the injection molding market for several years to come due to its devotion to technology, sustainability, and customization.