Sewage cleanup involves numerous health and safety risks for both workers and residents. Proper safety protocols are essential to mitigate these risks and ensure a safe environment. We will explore various safety measures and practices that must be followed during sewage cleanup operations. The focus will be on personal protective equipment (PPE), training, site assessment, decontamination procedures, and community safety. By adhering to these protocols, the dangers associated with sewage exposure can be significantly reduced.

Importance of Personal Protective Equipment (PPE)

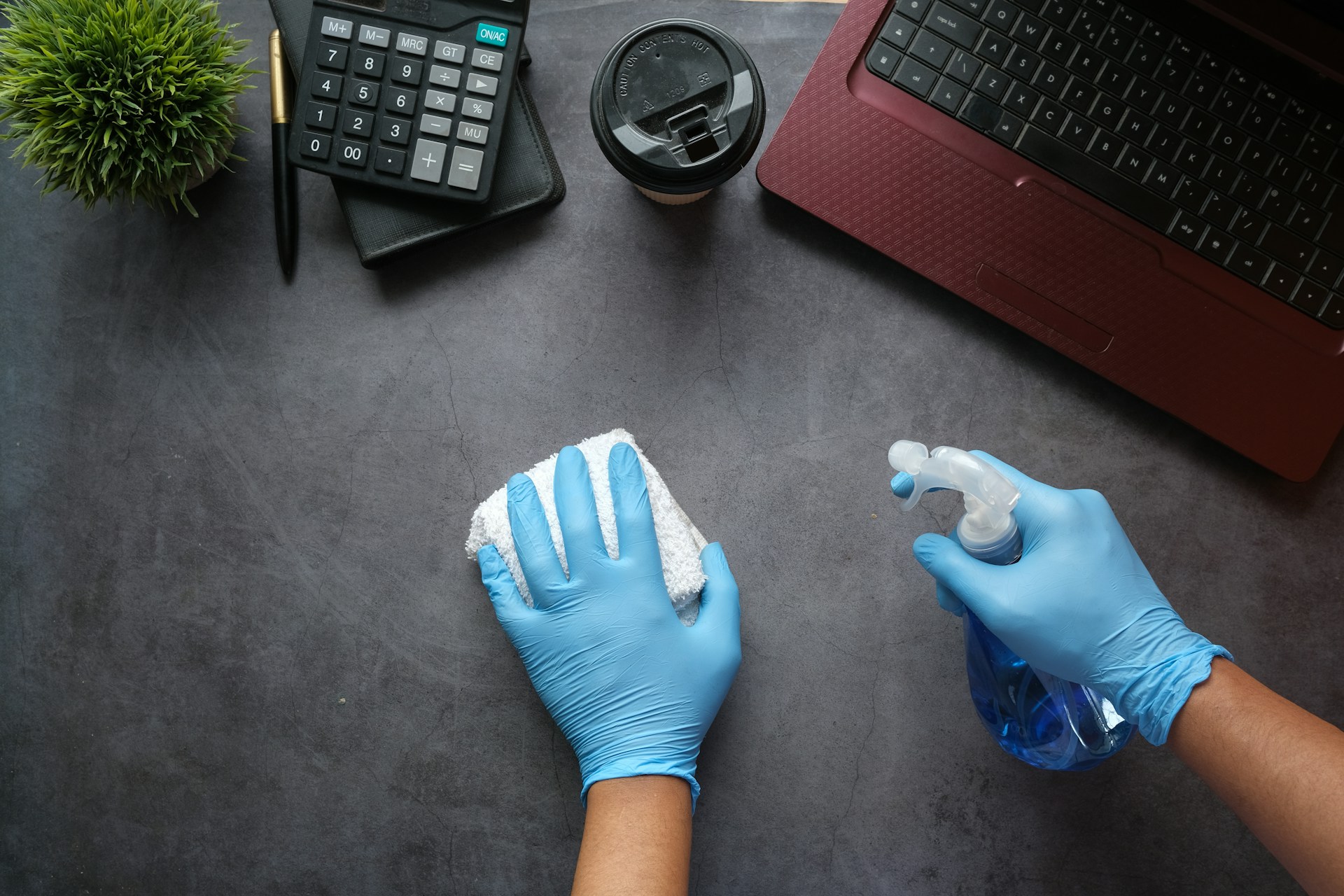

Personal protective equipment (PPE) is crucial in top-tier sewage cleanup in Seattle operations. It serves as the first line of defense against harmful pathogens and hazardous substances in sewage. Workers should wear appropriate PPE, including gloves, goggles, masks, and protective clothing. These items prevent direct contact with contaminants and reduce the risk of infections and injuries.

Gloves should be durable and resistant to punctures and chemicals. Nitrile or rubber gloves are often preferred due to their robust protective qualities. Goggles or face shields protect the eyes from splashes, while masks or respirators shield workers from inhaling harmful aerosols and gases. Full-body suits, made of materials resistant to biological hazards, provide comprehensive protection, especially in high-risk areas.

Employers must ensure that workers are adequately trained in properly using and maintaining PPE. Regular inspection and replacement of PPE are necessary to maintain its effectiveness. Proper disposal of contaminated PPE is also critical to prevent secondary contamination. By prioritizing using PPE, the health and safety of sewage cleanup workers can be significantly enhanced.

Comprehensive Training and Education

Training and education are fundamental components of a successful sewage cleanup safety program. Workers must be thoroughly trained on the hazards associated with sewage, the proper use of PPE, and the implementation of safety protocols. Comprehensive training programs should cover various aspects, including hazard identification, risk assessment, and emergency response procedures.

Training should be conducted regularly to ensure workers stay updated on the latest safety practices and regulatory requirements. It should include both theoretical knowledge and practical skills. For instance, workers should learn to correctly don and doff PPE, handle contaminated materials, and perform decontaminating procedures.

Education programs should also emphasize the importance of personal hygiene and health monitoring. Workers must understand the symptoms of potential infections and illnesses related to sewage exposure. Encouraging workers to report any health issues promptly can help in early detection and treatment, preventing further complications.

By investing in comprehensive training and education, employers can create a knowledgeable and skilled workforce capable of performing sewage cleanup tasks safely and efficiently.

Site Assessment and Hazard Identification

Conducting a thorough site assessment is crucial before commencing any sewage cleanup operation. A detailed evaluation of the affected area helps identify potential hazards and determine the necessary safety measures. Site assessment involves examining the extent of contamination, identifying possible sewage sources, and assessing structural integrity.

During the assessment, workers should look for signs of hazardous substances, such as chemicals, sharp objects, and electrical hazards. Identifying these dangers early on allows for implementing appropriate controls to mitigate risks. For example, isolating electrical systems and removing sharp debris can prevent accidents and injuries.

Additionally, air quality monitoring is essential to detect harmful gases and pathogens present in the sewage. Portable gas detectors can help identify the presence of toxic gases like methane and hydrogen sulfide. Appropriate ventilation and respiratory protection measures should be implemented if elevated levels are detected.

By conducting a comprehensive site assessment and hazard identification, workers can develop a tailored safety plan that addresses specific risks associated with the sewage cleanup operation.

Decontamination Procedures

Decontamination procedures play a vital role in preventing the spread of contaminants and protecting workers and residents. Proper decontamination involves thorough cleaning and disinfection of affected areas, equipment, and PPE. It is essential to use appropriate disinfectants that are effective against pathogens commonly found in sewage.

Workers should follow a step-by-step decontamination process. This typically includes removing gross contamination, washing with soap and water, and applying disinfectants. High-touch surfaces, such as doorknobs and handrails, should receive special attention as they can harbor pathogens.

Decontamination procedures should also extend to workers themselves. After completing cleanup tasks, workers should undergo thorough personal decontamination. This includes removing contaminated clothing, washing exposed skin, and changing clean attire. Proper disposal of contaminated materials, such as gloves and disposable suits, is crucial to prevent cross-contamination.

Employers should establish designated decontamination areas equipped with necessary supplies and facilities. Decontamination procedures are regularly monitored and evaluated to ensure their effectiveness and adherence to safety standards.

Sewage cleanup is a complex and hazardous task requiring meticulous safety protocol attention. We have explored the importance of personal protective equipment, comprehensive training, site assessment, and decontamination procedures. By implementing these safety measures, the risks associated with sewage cleanup can be effectively mitigated, protecting workers and residents. Employers, workers, and the community must work together to ensure a safe and successful cleanup process.