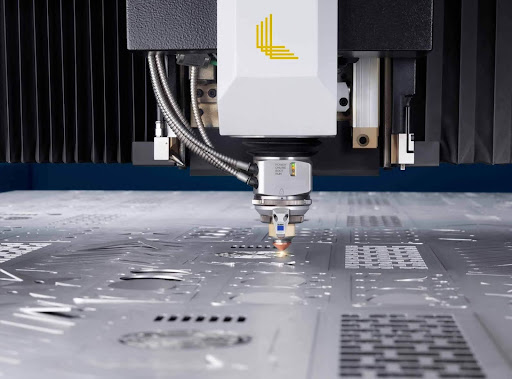

The advent and continuous improvement of laser cutting service technology have fundamentally transformed the manufacturing landscape. The evolution from traditional mechanical processing to advanced laser systems has not only increased precision but also introduced a plethora of opportunities for innovation across various industries. In this exploration of the future of laser cutting services, we will delve into how this technology is expected to evolve and continue to revolutionise precision and efficiency in manufacturing.

The Current State of Laser Cutting Services

Today’s laser cutting services prominently feature speed, accuracy, and versatility. They can work with a vast range of materials, including metals, plastics, wood, and glass, among others. This flexibility has enabled manufacturers to produce intricate designs that were once deemed too complex or costly.

Enhancements in Precision

One of the defining features of modern laser cutting technology is precision. The ability to produce components with exact specifications with minimal tolerances has been a game changer for industries such as aerospace and medical devices. Consistency in production runs ensures high levels of reliability and quality in finished products.

Innovations in Speed and Efficiency

The introduction of fibre lasers has accelerated cutting speeds substantially. These highly energy-efficient systems lead to faster turnaround times and more eco-friendly operations. Manufacturers can now undertake larger production volumes without compromising on quality, delivering to the market more rapidly and efficiently.

Software Integration and Automation

Another pivotal aspect has been the integration of sophisticated software with laser cutting machines. Advanced programming capabilities enable the automation of complex cutting patterns and sequences, as well as real-time adjustments during operations, cutting down on human error and reducing material wastage.

Laser Cutting: Peering into the Future

Projecting ahead, the trajectory for laser cutting services skews towards smarter, more connected systems with a focus on sustainability. Here are several anticipations that signal the future of laser cutting:

Intelligent Laser Systems

Industry 4.0 is ushering in a new era of smart manufacturing. Laser systems are expected to become even more intelligent, with self-optimising capabilities. They will be able to self-calibrate and adjust parameters for different materials, thicknesses, and shapes, providing unparalleled adaptability on the fly.

Laser Cutting and the Integration of IoT

The Internet of Things (IoT) will enable further integration of laser cutting machines into the manufacturing ecosystem. Real-time data collection from sensors embedded in laser cutters will offer insights into machine performance, predict maintenance needs, and help in scheduling operations to maximise machine utilisation.

Green Laser Cutting Technologies

As sustainability becomes a higher priority, laser cutting services are adapting to reduce their environmental footprint. Innovations in this area include the development of laser systems with lower power requirements and the recycling of scrap material generated during the cutting process.

Advancements in Material Processing

Researchers are continuously exploring new laser sources and settings to efficiently cut a wider range of materials. This ongoing research could soon result in laser cutting being a viable option for materials traditionally deemed challenging, such as certain grades of steel or composite materials.

Customisation and On-Demand Manufacturing

Laser cutting services are set to play a crucial role in the shift towards customisation and on-demand manufacturing. With laser cutters capable of quickly switching between designs, small production runs and one-off prototypes are cost-effective, catering to the consumer’s growing desire for personalised products.

Tailored Solutions and Industry Specificity

As laser technologies advance, we can expect to see tailored solutions designed to meet the specific needs of different industries. These sector-specific laser cutting machines and services will provide more precise results, enhance performance, and tackle unique challenges that different industries face.

Conclusion

The future of laser cutting appears radiant as technological advancements promise to usher in a new epoch of manufacturing excellence. The relentless pursuit of precision, efficiency, and adaptability continues to drive the industry towards a horizon where design limitations are a thing of the past, and innovative applications become commonplace.

Amidst this landscape of constant change, businesses looking to remain competitive will look towards leveraging a laser cutting service that can deliver the highest levels of accuracy and speed to bring their visionary designs into reality. As manufacturers and service providers adapt to these new technologies, the benefits of laser cutting will become even more pronounced – facilitating a manufacturing renaissance where the only limit is the imagination of those at the drawing board.

The Journey Ahead

In conclusion, the journey of laser cutting services towards unprecedented levels of precision and versatility is ongoing. With each innovation, the bounds of what can be achieved are being redefined, cementing laser cutting’s formidable position in the modern manufacturing process. As we witness the evolution of this incredible technology, the future of laser cutting not only seems bright; it shines with the promise of continual transformation and growth that will spark new possibilities in manufacturing.

In an industry where the currency is precision, laser cutting services hold the key to unlocking the next level of manufacturing prowess. Whether for intricate electronic components, robust automotive parts, or delicate medical implants, the laser cutter’s beam will surely lead the way into an era marked by refinement and innovation.